Over the past five years, automation and robotics have significantly transformed various industries, replacing manual labor and enhancing efficiency. The U.S. and China, as two of the world’s largest economies, have been at the forefront of this technological shift. This article explores the top industries affected by automation, compares its impact on the U.S. and China, and discusses the reduction in the cost of goods (COGS) due to these advancements. Additionally, it predicts which manufacturing disciplines will be most impacted by automation in the next five years.

Top Industries Affected by Automation and Robotics

- Automotive Manufacturing

- U.S.: Automation has been pivotal in the U.S. automotive industry, with robots performing tasks such as welding, painting, and assembly. Companies like Tesla and Ford heavily rely on robotics to enhance production efficiency and reduce labor costs.

- China: China, the world’s largest automotive producer, has rapidly adopted automation to maintain its competitive edge. Companies like BYD and Geely utilize advanced robotics for assembling vehicles, significantly improving production speed and consistency.

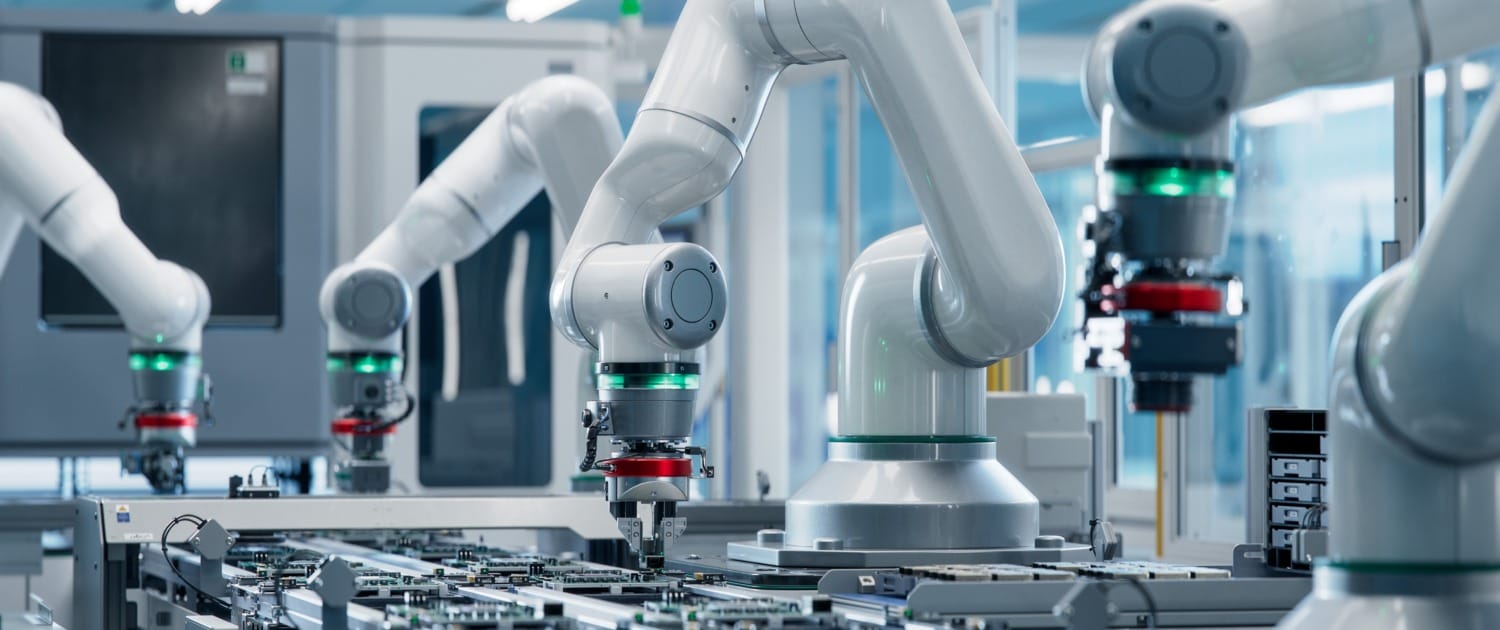

- Electronics Manufacturing

- U.S.: The electronics industry in the U.S., particularly in semiconductor manufacturing, has seen extensive automation. Firms like Intel and AMD employ robots for precision tasks such as silicon wafer handling and chip fabrication.

- China: In China, companies like Foxconn, which manufactures for Apple, use automation extensively in assembling smartphones and other electronics. This reduces reliance on human labor and minimizes errors in the assembly process.

- Food and Beverage Processing

- U.S.: Automation in food processing has streamlined operations in companies like Tyson Foods and PepsiCo. Robots handle tasks such as sorting, packaging, and quality control, ensuring consistent product quality and safety.

- China: Chinese companies, including Yili and Mengniu, have integrated robotics into their processing lines to meet growing demand efficiently. Automation in tasks like bottling and packaging has enhanced productivity and hygiene standards.

- Pharmaceutical Manufacturing

- U.S.: The pharmaceutical industry in the U.S. benefits from automation in drug manufacturing and packaging. Companies like Pfizer and Merck use robots to ensure precise formulation and packaging of medications, reducing human error and contamination risks.

- China: China’s pharmaceutical sector has embraced automation to scale up production. Firms like Sinopharm utilize robotics in drug production and packaging, improving efficiency and meeting regulatory standards.

- Textile Manufacturing

- U.S.: Although the textile industry has moved offshore in recent decades, automation is reviving some segments in the U.S. Companies use robotic looms and automated sewing machines to reduce labor costs and increase production speed.

- China: China, a global leader in textiles, employs automation to maintain low production costs. Robots in weaving, dyeing, and cutting processes enhance precision and reduce material waste.

Comparison of Impact on Cost of Goods (COGS)

The adoption of automation and robotics has significantly reduced the COGS in both the U.S. and China, though the scale and impact vary due to different economic contexts and labor costs.

- U.S.: Automation reduces labor costs and increases production efficiency, which in turn lowers the COGS. For instance, in the automotive industry, the use of robotics has cut down production times and minimized defects, resulting in lower overall costs. However, the high initial investment in automation technology can be a barrier for some manufacturers.

- China: While labor costs in China are generally lower than in the U.S., the adoption of automation helps Chinese manufacturers stay competitive globally by further reducing costs and improving quality. The extensive use of robotics in electronics and automotive manufacturing has led to significant reductions in COGS, enabling China to maintain its position as a leading manufacturing hub.

Future Trends: Industries Most Likely to be Impacted by Automation

Looking ahead, several manufacturing disciplines are poised to experience significant automation advancements in the next five years:

- Aerospace Manufacturing: Precision and safety are paramount in aerospace, making it a prime candidate for increased automation. Robotics will likely handle complex assembly tasks and quality inspections.

- Agriculture: Automation in agriculture, particularly in harvesting and planting, will grow. Autonomous tractors and drones for crop monitoring are expected to become more widespread.

- Construction: The construction industry will see more automation in the form of 3D printing for building components, robotic bricklaying, and autonomous machinery for excavation and site preparation.

- Medical Device Manufacturing: The demand for precision and consistency in medical devices will drive automation. Robots will handle intricate tasks in manufacturing and assembling medical instruments and implants.

- Logistics and Warehousing: The logistics sector will increasingly adopt autonomous vehicles, drones, and robotic sorting systems to streamline supply chains and reduce operational costs.

Conclusion

The past five years have demonstrated the transformative impact of automation and robotics on various industries in the U.S. and China. As these technologies continue to evolve, their role in reducing costs and enhancing efficiency will only grow. By staying ahead of these trends, industries can not only remain competitive but also set new standards for productivity and innovation

Contact Us

Follow Us