As the #1 manufacturer in the world China now produces nearly $2.5 trillion of goods. While this is around 28% greater than the U.S., manufacturing makes up an astounding 30.5% of China’s GDP vs. 12.3% for the U.S. One thing experts acknowledge is at $2 trillion in manufactured output the U.S. produces more with less labor. It also indicates that low value added jobs with less profit margin have gone and remain overseas. So what does that mean for us? It means that China is still the factory to the world and if operations decision makers haven’t developed a competent model to outsource redundant, high labor and low value add processes, they are tempting fate. There is a cost to and not to doing business in China. and the time has come for most organizations to analyze synergistic offshore-onshore manufacturing & distribution strategies.

Assume for a moment that you are the SVP of Operations for a U.S. firm in Des Moines that manufactures some sort of metal and plastic assembly. Sales have been flat and finally in that Monday morning meeting the inevitable question arises. “What are we doing about China?” your boss asks. You have a solid team of purchasing professionals, none of which can point to Hong Kong on a map. However, through the internet one of your go-getters, Bill, has begun to put a spreadsheet together of die cast and injection molding companies in the Guangdong Province, which he’s researched as being a hotbed for these industries. Since Guangzhou is a FTZ (Free Trade Zone) Bill with his Operations Management degree, has identified this as the logical place to start. He’s shared a couple of months of emails with “agents” posing as direct factory managers and is ready to take his associates to China. Just say the word.

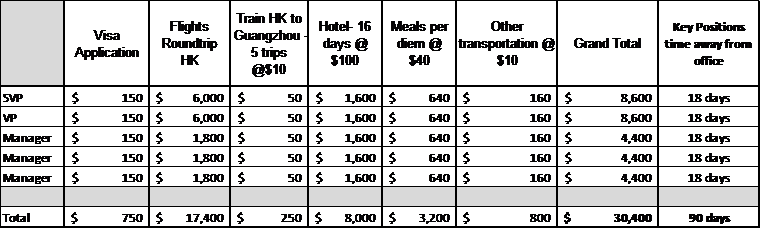

Assuming that Bill and the others now have passports and visas in hand, they begin booking flights, hotels, trains, and ferries to venture out into the Middle Kingdom. In all they’ll be gone for just under three weeks. Since this is the company’s first sojourn to Asia, you’ll undoubtedly accompany them on this exciting new foray into the land of the dragon along with your Ops VP. Now you and your four valuable employees will be out of pocket the majority of a month leaving yours and their day to day responsibilities to others or to simply take a break from existing projects. How much time and capital do you think this will require? You may be surprised.

The following lists conservatively typical expenses by line item for a 2 ½ week trip to China.¹ Remember, you’ll require a full 24 hour day of travel to and from and a day of recovery once you’ve arrived.

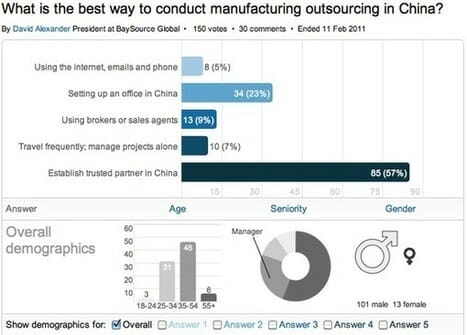

The good news is there are competent firms in place to assist in your project management initiatives. In a poll on Linked In, 150 Supply Chain professionals weighed in with their response to the question, “What is the best way to manufacture outsourcing in China?” (See diagram below). 57% of respondents chose “Establish a trusted partner in China.” Perhaps a good portion of the voters had already been through the trial and error process. Or it could be that those who have succeeded in tandem with a firm watching out for their best interests can easily quantify the decision to engage a reputable partner for monitoring manufacturing, quality control, packaging, labeling and logistics.

In his article https://baysourceglobal.com/10-tips-to-better-china-sourcing/ William Atkinson of Purchasing Magazine explains that regardless of their China story, those who have enjoyed a successful relationship with China have done so through proper guidance and preparation. In this critical juncture of global commerce, fluctuating currencies, and competitive pressure, it is imperative to select a reliable partner whom you can trust, knows the local governments and regulations, has engineers on staff who understand your products and who can help you gain a foothold in this valuable region of the world.

¹Airfares, four star accommodations and RMB exchange rates as of September, 2014

Baysource Global President, David Alexander can be reached at david.alexander@baysourceglobal.net

Follow Us