Products & Capabilities

Baysource connects you with vetted factories that match your design, quality, and production goals. No retrofits. No guesswork. We specialize in sourcing and managing manufacturing for consumer and industrial products, with built-in quality control and real-time visibility from prototype to delivery.

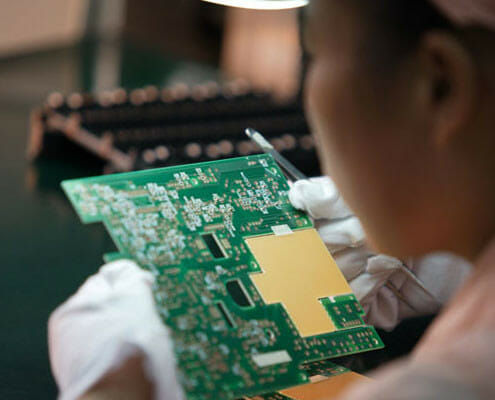

Explore our manufacturing capabilities across plastics, metals, electronics, packaging, and more.

Still developing your product?

Before you go to market, make sure your strategy is solid. Check out our guide to the 6 key steps every product developer should follow.

- Injection molded plastic parts and assemblies

- Cut and Sew

- Custom designed next generation products

- Electro-mechanical

- Furniture—wood, metal and other

- Finishing-powder coated, dipped, chrome and other finishes

- Primary and secondary packaging; custom printed artwork

- Ceramics

- Outdoor living

- Projects that require disciplines across a wide variety of materials

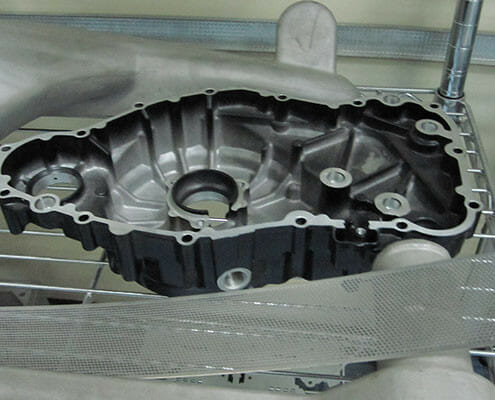

- Mechanical components cover the spectrum of all plastics grades, ferrous and non-ferrous metals and cast metal parts.

- Injection Molded Assemblies; all grades of commodity and engineering grade plastics. Single and multi cavity tools. Single shot, double shot and over molding options.

- Stamped Assemblies, Progressive, Deep Draw, Transfer and Single Operation pressings available in all grades of ferrous and non-ferrous metals. Spot welding and all painting types available.

- Cast Components & Assemblies; Pressure casting in Magnesium, Aluminum & Zinc, Investment

- Casting in steel and stainless steel. CNC machining, sand blasting, polishing, painting and lacquering options available.

- Projects requiring a high degree of value added engineering and quality control services

Quality Control That Matches the Product

Every product requires a different level of oversight. That’s why our quality control processes are tailored to the technical and performance demands of your specific build.

Before production, we audit factory capabilities and inspect materials to ensure they meet your standards. During production, in-line checks with photo reports confirm real-time compliance. Final inspections before shipment reduce the risk of delays or rework.

Our approach includes:

- Factory audits focused on equipment, staffing, and materials

- Sample review and specification confirmation

- Real-time quality checks at key stages of production

- Pre-shipment inspections with detailed documentation

We prioritize prevention over correction. That means identifying issues early, not reacting to them later.

EXPLORE OUR CASE STUDIES

Explore how Baysource’s tailored manufacturing solutions have helped companies across industries bring products to market with confidence, quality, and cost efficiency.

Ready to Start Your Next Project?

With over 30 years experience assisting companies in supply chain excellence we accelerate goals while mitigating risk. Let us know more about your project below. All inquiries will be answered within 24 hours.

North America Operations

1010 S.Rome Ave

Tampa, FL 33606

+1 (813) 251-4184

Asia Operations

Building 15, 3F

271 Qianyang Road

Shanghai 200333

China

Follow Us